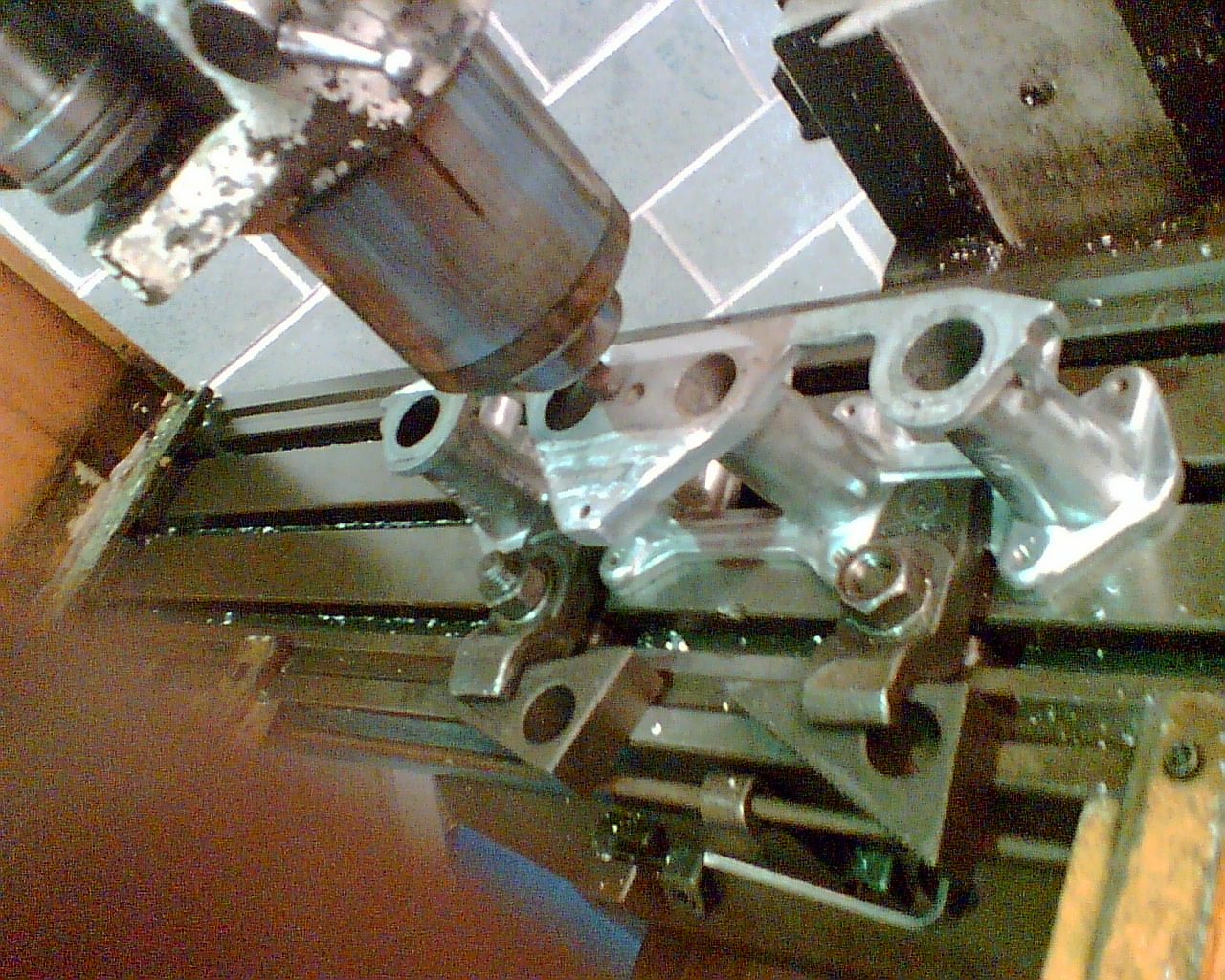

The above photo shows a standard Holbay manifold as fitted to the Hunter gls/Rapier h120. AS it was fitted at a 7 degree angle it needs to be machined flat, this would leave 1 side thin so prior to machining it has been built up with weld. Next its been clamped to the bed of a vertical milling machine & milled flat with a fly cutter to minimise distortion through heat.

Using the inlet manifold gasket as a guide all ports were enlarged to suit & polished to improve air flow

<div align='center'><a href='http://www.businesslogo.net'><img src='http://www.hit-counts.com/counter.php?t=0&digits=4&ic=0&cid=459555' border='0' alt='Corporate Logo Design'></a><BR><img src='http://www.hit-counts.com/webstatistics.php?metid234=459555&pagename=index' width='1' height='1'><a href='http://www.hit-counts.com'>Hit Counter</a></div>